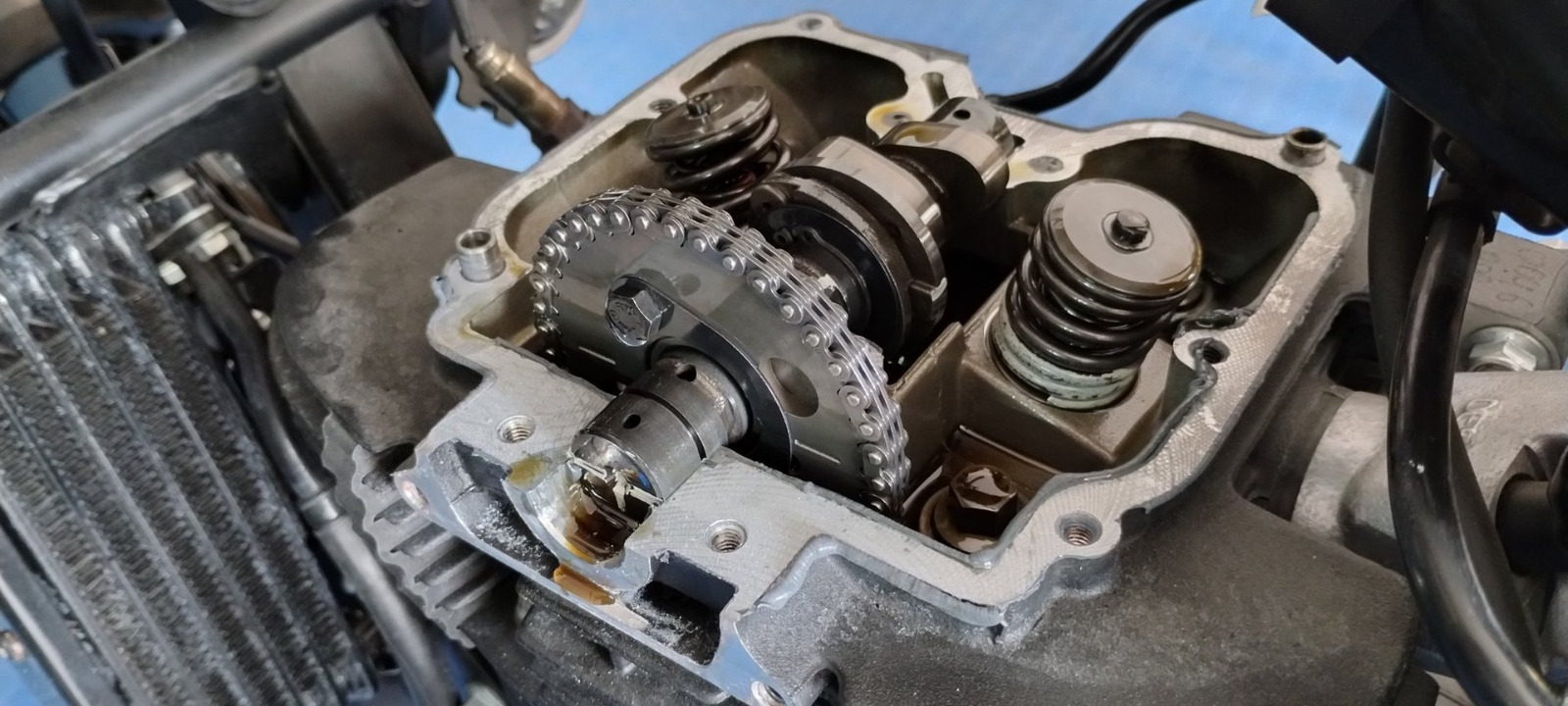

Hi, looking at the valves of my motorbike I noticed that the exhaust stem, where the tappet works, has a convex surface facing upwards. I wonder how it is possible to adjust the valve clearance since we would be working on the edge with the feeler gauge.

I only have this photo but the problem is visible.

Has anyone who is more experienced ever noticed this?

I only have this photo but the problem is visible.

Has anyone who is more experienced ever noticed this?