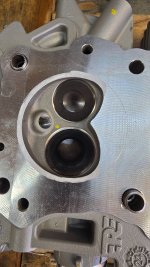

Using oil paint from the Craft store ( Bearing Blue is not easy to obtain these days ) I have smeared a small amount on the Valve face.

Then using what some may refer to as a Lapping tool I have inserted the Valve into the Head and rotated it leaving behind an indication of seating contact area.

The Valve also shows an indication.

Basically where they touch the Blue comes off and stays on the Head/Valve seat.

I now have to wait for the correct sized (6mm) arbor to arrive that will enable me to change the position of the contact on the Valve.

My preference ( although what is shown here is adequate ) is for a thinner contact line and one that is closer to the Stem which will in effect raise the Valve out of the Seat.

This tool holds the cutting tip that will "Crown" ( cut the top ) of the Seat, as you may be able to determine,the tool is inserted into the Valve Guide with various different angled cutters held at 90deg.

The Seat contact area is cut to 45deg so I will be using a 30deg cutting angle to Crown the seat and bring the Valve contact area closer to the valve stem.

Had I wanted to go the other way I would be using a larger angle such as 70deg and "Throating" the seat.

When finished I will NOT be lapping the valve with grinding paste !

Another advantage of a thinner seat contact area is that the Pressure holding the Valve to the seat is greater.

Same Force on less Area equals more Pressure.

P = F/A can't argue with Physics